- Service

- …

- Service

- Service

- …

- Service

Cable Extrusion Line

Cable Insulation Line, Cable Sheathing Line, Wire Extruder

Introduced our high-speed wire extrusion line specifcally designed for the manufacturing of building wires. Our cable extrusion machine allows you to select specifc screws and barrels to match various extrusion materials, included PVC, PE, LSNH, Teflon, and Nylon.

Excellent Cable & Wire Extrusion Line Machine Manufacturer

Cable extrusion lines are industrial lines that wrap metal wires in plastic insulation, but when it comes to cable extrusion, customization is key.

Depending on your exact needs, production space and speed requirements, there are many options to make your extrusion line not only meet your precise specifications,

but also optimize productivity and reduce operating costs.

SJ-WE-30, SJ-WE-40, SJ-WE-50, SJ-WE-60, SJ-WE-70

SJ-WE-60, SJ-WE-70, SJ-WE-80, SJ-WE-90

APPLICATION:

Extrusion of PVC, ZHLS, Nylon, halogen-free environment-friendly polymers.FEATURES:

• PLC+HMI industrial computerized operations with display, memory and

retrieval of parameters. Automatic control and adjusting production line.

• Equipped with advanced special universal Cross-head, two-layer

Crossed-head, fulfilling the precision extrusion requirements.

• Specially designed screws to fulfill different kinds of material extruding.

• Max speed: 500mts/minSJ-TEF-WE-40, SJ-TEF-WE-50, SJ-TEF-WE-60

SJ-CF-WE-30+20, SJ-CF-WE-40+30, SJ-CF-WE-50+35

SJ-CF-WE-20+35+20, SJ-NF-WE-30+65+40, SJ-NF-WE-30+80+40

Suitable for CATV, RG, SYWV, JIS series.

Suitable Material: FM-PE, PE.

Foaming limit : High-pressure nitrogen injection (Max):78%, low pressure nitrogen system (Max): 70%.

Quality control : in-built outer diameter scanner, capacitance examination equipment.

Electronic control : PLC with HMI screen controlsSJ-WE-50+30, SJ-WE-60+40

SJ-FW-WE-50-26D, SJ -FW-WE-70-26D, SJ-FW-WE-80-25D

SJ-R-WE-50, SJ-R-WE-70, SJ-R-WE-90, SJ-R-WE-100, SJ-R-WE-120, SJ-R-WE-150

SJ-WE-90, SJ-WE-100, SJ-WE-120, SJ-WE-150

APPLICATION:

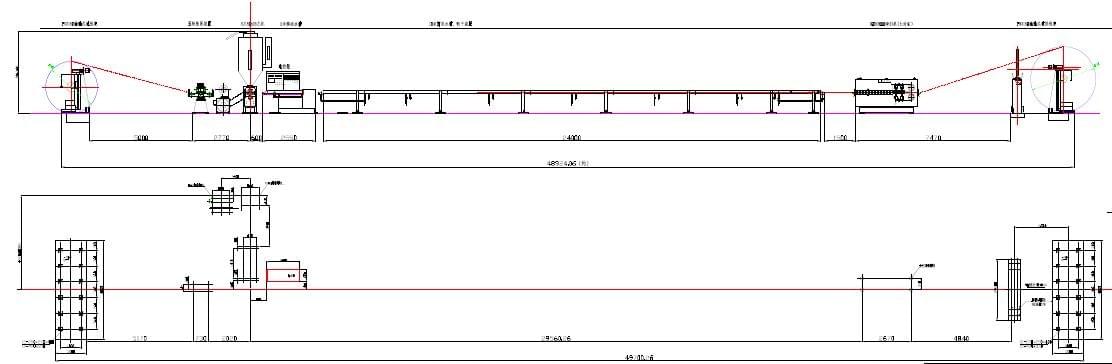

Production of insulated electrical power cables.LINE CONFIGURATION:

The line is made up of gate type pay-off, caterpillar tractor, extrusion host, control panel, cooling trough, spark tester, pulling caterpillar and take-up unit. Varous accessories can be added like printing mahchine, diameter controller, PLC and touch screens.Triple Co-extrusion Line

SJ-65+90+120 (0+3) 6-35KV Three layer co-extrusioncrosslinking production line

APPLICATION:

This production line is mainly suitable for the production of silane cross-linked cables and Aerial cables with voltage grades of 6 to 35 KV. The production line is warm water cross-linked production line.

Voltage level: XLPE: 6 ~ 35 kV

Conductor section: copper core: 35 ~630 mm2

Aluminum core: 50 ~ 800 mm2

Max cable weight: 10 kg / M

maxdiameter: Φ 70 mm

Extrusion thickness: Φ 65 machine internalshielding: 0.5 ~ 2.0 mm

Φ150 machine Insulation layer: 3.4 ~12 mm

Φ 90 machine external shield: 0.5 ~ 2.0mm

Cross linked closure length: 108m

Heating section: 36 m: 6 m ×Section 6

Precooling section: 12m: 6M ×Section 2

Water cooling section: 54m; 6m ×Section 9

Platform area of main building;(long) ×Width) ≥ 18m × 12 m

Floor height of main engine: ≥10 m

Plant length: ≥135 m

Main Component

| Pay-off | Tension Device | Exturder | Machine Head | Feeding and Drying Device | Cool Water Sink |

| Blow Dryer | Diameter Test | Spark Machine | Traction Device |

| Pay-off and Traverse Line Machine | Electrical Control System |

Layout of Cable Extruder Machine

Insulation production line for power cable and building cable;

Sheathing production line for power cable and building power cable;

Low somke halogen free cable, nylon sheath, PU extrusion line;

Precision fluoroplastic teflon (high temperature) extruder and double color machine;

Drawing and insulating tandem line;

Silicone Rubber extrusion line;

FEP PFA tube extrusion production line.

Running Video of Extrusion lines for wire and cable

We sold cable extruder to many countires below:

Brazil: 7

Azerbaijan: 6

Türkiye: 2

Bangladesh: 3

India: 1

Vietnam: 3

United States: 2

Model of Wire Extruder and Sheath Line

High Speed SJ-70X25 N12 Nylon Coating Line Exturder for Galvanized Wire

High Speed SJ-70X25 N12 Nylon Coating Line Exturder for Galvanized Wire 65 + 35 Dooble Layer Insulating and Sheathing Extruder Production Line

65 + 35 Dooble Layer Insulating and Sheathing Extruder Production Line 70+120+90 Triple co-extrusion line for 10kv cable

70+120+90 Triple co-extrusion line for 10kv cable 50+35 LAN Cable Extruder Machine For CAT5/6/7 Cable

50+35 LAN Cable Extruder Machine For CAT5/6/7 Cable SJ-150/25 Power Cable Jacket Extruder Machine

SJ-150/25 Power Cable Jacket Extruder Machine 80+90mm Photovoltaic PV Wire Tandem Cable Extrusion Line

80+90mm Photovoltaic PV Wire Tandem Cable Extrusion Line SJ-70/12 Silicone Rubber Cable Extrusion Production Line

SJ-70/12 Silicone Rubber Cable Extrusion Production Line Экструзионные линии От 2 – до 150

Экструзионные линии От 2 – до 150 SJ-70+35 High Speed Extruder Line With Automatic Coiling Machine

SJ-70+35 High Speed Extruder Line With Automatic Coiling Machine SJ90+35mm Photovoltaic cable Wire Extrusion Machine

SJ90+35mm Photovoltaic cable Wire Extrusion Machine Высокоскоростная экструзионная линия SJ70+35

Высокоскоростная экструзионная линия SJ70+35 CT-90 Cable Extrusion Line For Flat Cable

CT-90 Cable Extrusion Line For Flat Cable Photovoltaic PV Cable Extrusion Sheathing Machine

Photovoltaic PV Cable Extrusion Sheathing Machine 120mm Extruder Extrusion Machine Cable Sheath Line

120mm Extruder Extrusion Machine Cable Sheath Line Dual Sheath and Dual Colore Cable Sheathing Machine SJ50+70 With Automatic Coling Machine

Dual Sheath and Dual Colore Cable Sheathing Machine SJ50+70 With Automatic Coling MachineFrequently Asked Questions (FAQ) About Cable Extrusion Machines

Please send us requests for quotation, or you can speak to our engineer by emailing or giving a call.

What information should you provide if you want to get offer?

What is the different from common extruder and high speed extruder?

What model of extruder for manufacturing LAN Cat5/6/7?

What model of extruder for manufacturing building wire,power cable?

What model of extruder for manufacturing high frequency cable(USB3/1 HDMI)?

© 2019 Right: Beyde technology design