The development history of China's cable industry

If you want to develop the chinese market, we need to know the history of cable development in China.

In March 1897 (Emperor Guangxu of Qing Dynasty), the first underground power cable in China was put into use in Shanghai. The 2700 meter long rubber insulated lead sheathed lighting cable used in that year was imported. It was not until forty-two years later (1939) that the first domestic cable was produced in Kunming (cable factory). Before 1949, the wire and cable industry had only 2000 employees, about 500 production equipment, and the annual maximum copper consumption was only 6500 tons. Among them, Kunming, Shanghai, Tianjin and Shenyang electric wire plants share 5700 tons of copper, accounting for 87.7% of the total production, and the development of wire and cable industry is slow. It was not until 1949 when the new China was founded that the wire and cable industry in China developed rapidly.

After the founding of the people's Republic of China, the wire and cable industry has developed rapidly. In 1952, the conductor volume reached 15300 tons, 2.63 times that before the founding of the people's Republic of China.

During the "first five year plan", the wire and cable industry began to develop healthily and systematically. In 1953, the direct electric wire and cable factories under the Ministry of machinery were Kunming, Shenyang, Tianjin, Shanghai, Xiangtan and Harbin, etc. Shenyang electric power plant is one of the key national construction projects, which was expanded by the Soviet Union, and was put into operation and renamed Shenyang cable factory in 1956. Shanghai Electric Wire Factory expanded workshop, insulation line workshop and prepared to build cable workshop, and renamed Shanghai cable factory in 1957. Tianjin electric wire factory imported the drawing machine and paint wrapping machine of Hungary, built a new paint coating line workshop, and transferred it back to the Ministry of electronics industry to be renamed as 609 factory in 1963.

At the same time, the state gradually carried out socialist transformation of the rapidly developing private electric wire factory, and took rectification measures against the phenomenon of repeated products, backward technology and poor quality at that time. Shanghai merged 105 private factories into 18 central plants, 65 private factories were merged into 10 cable factories in Tianjin, 17 were merged into Beijing electric wire plants, 18 plants were merged into Guangzhou electric wire plants in Guangzhou, 3 factories were merged into Wuhan Electric Wire plants in Wuhan, and 10 factories were merged into Fuzhou rubber wire plants in Fuzhou. Through joint venture reorganization, the technology and governance level have been improved and production development has been promoted.

In order to solve the problem of special equipment in the wire and cable industry, the private Shanghai new industry iron plant was reorganized into a public private joint venture Shanghai new industry electrical machinery factory, which mainly produced cable equipment. From 1952 to 1957, 221 special equipment for electric wires and cables were produced.

In order to carry out the research and design work of combining scientific research, process design and process equipment design, Shanghai Cable Research and design office was established in Shanghai in October 1957. It is engaged in the research and design of wire and cable products, new materials and new technology research, cable plant process design, cable special equipment design and complete equipment selection and finalization, and it is used as the rear of layout technology and the wire and cable industry The intelligence center of.

In order to improve the level of enterprise governance, Shenyang cable factory has compiled the production organization design of continuous operation enterprise based on the study of Soviet Union enterprise governance. Subsequently, Shanghai cable factory has formulated the working procedures and methods of production operation plan, material cost quota accounting, new product trial production, production technology preparation, etc. Other major plants also carried out planning, production, technology, governance and economic accounting, which made the level of corporate governance improve.

In 1958, the power and cable factories of various regions competed to develop, and five cable factories, including Zhengzhou, Xi'an, Lanxi, Baiyin and Guiyang, were built, and three factories of Xiangtan, Kunming and Shanghai were expanded on a large scale. Zhengzhou cable factory started construction in 1959 to complete the civil engineering of cable workshop, and continued to be built after the design scale was revised in 1963. Xi'an cable factory was constructed by Harbin electric wire factory. After completing civil engineering of communication cable and electromagnetic line workshop and producing some products in 1959, it was suspended in 1962, and then copper network workshop was built and put into operation. In 1965, the communication cable workshop was moved from Shenyang cable factory and put into operation in that year. It was clear that communication cable was the product development direction.

Shanghai Cable Factory built a new calendering workshop, cable workshop, communication cable workshop and expanded the cable workshop from 1958 to 1962, with a large expansion of production capacity. Xiangtan cable factory was expanded in 1959, and the electromagnetic line workshop developed the production of electromagnetic line, plastic, rubber sleeve, mining and marine cable in 1964. Kunming Cable Factory was expanded in 1958, electromagnetic line workshop and cable workshop, and was suspended in 1961 after the construction. Shenyang Cable Factory built the cable workshop in 1960, and Harbin Electric Wire Factory expanded the calendering and drawing aluminum wire workshop. The 609 plant was also expanded during this period.

During this period, a number of small and medium-sized electric wire factories, such as Wuxi, Wuhan, Tianjin, Beijing and Qingdao, were established on the basis of joint venture restructuring, some of which were expanded and some relocated to build factories. In addition, Chongqing, Hengyang, Foshan, Nanning, Kaifeng, Suzhou, Hangzhou, Xi'an, Wuhu, Beijing, Xingtai, Yuci, Liaoyuan, Harbin and other places have set up many electric wire factories, electromagnetic wire factories and wire mills. Some wire and cable factories have been established in the post and telecommunications and railway sections.

During this period, some cable accessories factories have been developed, such as Wuhan cable accessories factory, Changsha cable accessories factory, Wuxi plastic products factory, Shanghai Wuning hardware factory, etc.

In 1958, Shanghai Cable Research and design office was renamed Shanghai Cable Research Institute. From 1959 to 1960, various laboratories and machine repair workshops were built, and the civil engineering of the high-voltage building was completed. In 1961, the general used high-frequency and undersea communication cables back to the Tenth Research Institute of the Ministry of defense, and later developed into 1423 Research Institute.

The number of wire and cable factories increased from 136 in 1958 to 44 in 1965, and the situation began to improve.

From 1967 to 1968, Hubei Hongqi Cable Factory was built by Shanghai cable factory. After completion, its main products are ultra-high voltage cable, submarine communication cable, marine cable and XLPE cable. In addition, Shanghai Dalai electric power plant moved to Lanzhou and merged with Baiyin cable plant to build Changtong electric wire plant, Shanghai plastic wire and aluminum wire plant moved to Guiyang electric wire plant, Qingdao electric wire plant moved to Xintai electric wire plant, Fuzhou electric wire plant moved to Nanping electric wire plant, Harbin electric wire plant moved to Mudanjiang electric wire plant, Hangzhou electric wire plant and Wenzhou electric wire plant Some of them moved to Shanhe electrical equipment factory, Wuxi cable factory moved to Guangde wire factory, Guangzhou wire factory moved to Huaxian wire factory, Shenyang cable factory moved to Fushun Qingyuan to 8290 wire factory.

From 1966 to 1976, a number of new factories were built. The Ministry of Posts and telecommunications has established Houma cable factory, the Ministry of Railways has established Jiaozuo railway electrical equipment factory, Tianshui railway cable signal factory, etc.

Since the reform and opening up, China's wire and cable industry has achieved rapid development.

The convening of the Third Plenary Session of the Eleventh Central Committee and the implementation of the sixth five year plan of the people's Republic of China have brought about a new upsurge in the enthusiasm of employees in the cable industry. In 1979, the consumption of conductors rose to 439200 tons. After the center put forward the policy of "adjustment, reform, rectification and progress" in 1979, China's infrastructure scale was greatly reduced, and the demand for wires and cables decreased. However, with the development of household appliances industry, the demand for some products, such as fine enameled wire, increased sharply. With the results of the adjustment, production picked up, and the consumption of conductor increased to 623000 tons in 1985.

With the development of the reform and opening up, the inter regional and inter industry enterprises have developed rapidly. At the same time, a large number of township enterprises and local enterprises have sprung up, which is unprecedented in the past. However, until the 1990s, state-owned enterprises had an unshakable dominant position in China's wire and cable industry. In the 1980s, Shenyang cable factory and Shanghai cable factory were established, and in the 1990s, Shenyang cable factory, Shanghai cable factory and Zhengzhou Cable Factory were formed.

With the deepening development of reform, from the mid-1990s, state-owned enterprises gradually withdrew from the historical stage, and the proportion of private enterprises in the industry increased year by year. During the ten years of development of the ninth five year plan and the tenth five year plan, the economic composition of China's wire and cable industry has also undergone major changes. In the early stage of reform and opening up, it was mainly composed of state-owned economy, supplemented by collective economy, and relatively single economic component. After the reform and adjustment during this period, it has gradually changed into a situation in which private enterprises are the main body of the market, foreign-funded enterprises occupy a large number of high-end markets, and the market share of state-owned enterprises is shrinking.

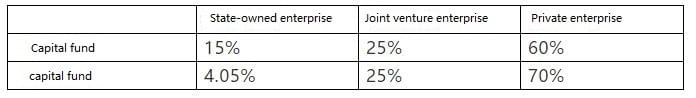

The following is the ownership pattern of China's wire and cable industry at the end of the Tenth Five Year Plan:

Table 3.1 ownership structure of China's wire and cable industry at the end of the Tenth Five Year Plan

Source: Shanghai Cable Research Institute

According to the industry survey in the late 1980s, the output value of state-owned enterprises designated by the original state accounted for 48% of the total industry output value. By 2004, the output value of state-owned enterprises decreased to only 4.05% of the whole industry. The proportion of private enterprises' output value increased from 40% to over 70%, which shows that private enterprises have already taken the leading position in the industry. Moreover, some private enterprises have completed capital accumulation, and production equipment and management have been on a step. Some excellent private enterprises even exceed the designated enterprises of the original state. At the same time, the three capital enterprises have completed the initial stage and entered the period of expansion. In 2004, among the top ten enterprises in China, only Jiangsu Baosheng Group Co., Ltd. is a state-owned enterprise, and the rest are three capital enterprises or private enterprises.

In recent years, China's cable industry has been shuffling its brand again, and state-owned enterprises have become the focus of enterprise annexation and reorganization. Nowadays, the transformation of Chinese cable industry enterprises and the reorganization of assets have entered the stage of white heat. In terms of the largest cable enterprises in the country, the merger, merger and acquisition of enterprises and the reorganization of assets are very fierce. The largest Shenyang cable factory in Asia has been disintegrated, and some of them become Japanese funded Shenyang Guhe cable company. Shanghai Cable Factory no longer exists, and two-thirds of its assets have been jointly invested with Japanese Fujikura. Zhengzhou Cable Group Company is also salivating by many Chinese and foreign companies, and was invested and controlled by China Science and technology Yinghua High Technology Co., Ltd. in 2007. Hongqi Cable Factory, a large cable enterprise in the central China, has been merged by private domestic cable enterprises with strong strength. Inner Mongolia cable factory has been annexed by Shanghai Cable Co., Ltd. It is said that Nanning Yinshan cable company, a Southwest old cable company, is also being swallowed up. The merger of state-owned enterprises not only deduces a kind of tragic and heroic Chinese state-owned cable enterprises, but also deduces their fate. Their brilliant achievements have become a glorious page in the history of Chinese cable.

Since the reform and opening up, China's huge wire and cable market has attracted cable manufacturers from developed countries to invest in the construction of plants, and has achieved good results. Foreign capital has built a power and cable factory in China, with a wide range of products, covering almost all the wire and cable products, from 220-500kV high voltage and ultra-high voltage cross-linked cables to small electronic cables, all have everything, and the factory scale is large and small. These foreign capital mainly come from Japan, the United States, the United Kingdom, France, Germany, the Netherlands, Switzerland, Singapore, as well as Hong Kong and Taiwan, China. Prysmian (prissman Italy), Nexans (nexen France), Pirelli (piralli), Sumitomo (Sumitomo), Furukawa (Guhe), Siemens (Siemens) have established joint ventures and sole proprietorship enterprises in China. Their purpose of building factories in China is to make high-level products by using cheap labor and preferential policies in China. They can not only obtain market share in China, but also participate in international competition with low cost and maximize profits. These cable alligators have occupied a large part of the domestic high-end cable market, and have made remarkable achievements and have made great achievements in China market. Among them, prisman and Baosheng have cooperated to build UHV cable production line. The 110-220kV cross-linked cable of Japan Guhe electric engineering and Huaxin Lihua, Taiwan, has occupied a considerable market share in China. The special cables and transportation cables of nexen company in France have a high reputation in China and are constantly entering some key projects. Philips and Siemens have long been known in China. The ACCC wires of CTC company of USA successfully entered the Chinese market and started to build manufacturing base. There are also many companies that make enameled wires, electronic wires, power lines, etc.

In terms of private enterprises, not only their output value has accounted for more than 70% of the total output value of China's wire and cable industry, but also has formed a number of large enterprises with great influence in the industry, which has led to the formation and development of China's wire and cable industry cluster.

Yixing City, Jiangsu Province, has developed into the largest production base of electric wires and cables in China since the middle of last century. Far East Cable Co., Ltd. has an annual output value of 40% increasing evenly. In 2006, it has completed the industrial output value of more than 10 billion yuan, becoming a famous and vice real industry "giant alligator". Guanlin town has built a famous "China cable city" in the industry, with the main products of power cables, with an annual output value of more than 100 billion yuan.

Wujiang District, Suzhou, Jiangsu Province has formed a communication cable and optical cable production base with several large enterprises such as Hengtong group as the leading part, which occupies half of the top ten products in the country.

The power cable production enterprises with cable above Liyang City as the leading part of Jiangsu Province have gradually grown into the benchmark of domestic cable enterprises. Its lean cost control makes it difficult for domestic enterprises to reach.

In North China, the power cable industry bases, represented by Baofeng cable group, Xinhua cable group, Tianjin plastic cable group, Yongjin cable group, Hebei Huatong Group, etc., are mainly distributed in Ningjin, Hejian, Bazhou and other counties and cities, and the main products are also power cables and rubber sheath cables.

Guangdong Pearl River Delta is the most fair industrial concentration of China's wire and cable industry structure. In addition to Guangdong cable factory, Nanyang cable factory, Xinya optical cable factory and large-scale cable enterprises, the region also has a large number of specialized enterprises which mainly produce special cables for electronic cables and electrical equipment with high added value, and have a large number of products export. Humen is the main export area of China's wire and cable.

Anhui Province has formed a special cable production base with Wuwei County as the core, and is striving to build the largest high-tech industrial base of special electric wire and cable in China.

Shandong Province has formed a number of leading wire and cable industry bases with several key enterprises, namely, Hanhe, Luneng (special change of Shandong cable) and Yanggu, Shandong Province, which has a considerable market share in the industry.

The cable base includes Yixing Guanlin Town, Wujiang City, Jiangsu Province, Qidu Town, Gaogou Town, Wuwei County, Humen Town, Dongguan, Ningjin County, Hebei Province, and the exchange of images and competing for glory.

Yangtze River Delta region, with a complete industrial chain, occupies half of the cable industry. Power cable enterprises, Jiangsu five factories far east, Shangshang, Baosheng, Hengtong, Zhongtian. These enterprises actively transform and create core products on the basis of complete industrial chain. The Far East is transforming new smart energy, and the power cable is the foundation, nuclear power cable and rubber sleeve cable are the profit points to deepen lean production. Baosheng was acquired by AVIC industry, which is a small number of state-owned enterprises. After the layout of high-pressure cable, Hengtong Group actively arranged the strategy of going out and built factories in multiple countries.

In addition, the industrial cluster effect is also preliminarily included Zhejiang Wenzhou cable City, Hangzhou Lin'an cable City, Nanping cable City, Hunan Hengyang Jinbei cable City, etc.

The rise of "cable city" is not only a beautiful scenic line of China's wire and cable industry, but also a symbol of the beginning of China's wire and cable industry to mature. Of course, the cable City mentioned here is not the concentration of commodity sales stall in the market, but the collection of large-scale wire and cable manufacturing plants and related industries, which is the preliminary form of industrial cluster. The formation, development and maturity of industrial clusters will become an important sign of the gradual development and growth of China's wire and cable industry. Most of these areas are not strictly related to the industrial clusters of wires and cables, only the rudiments. In fact, these cable cities are basically regional industrial cooperation organizations, and the relatively concentrated of many wire and cable manufacturers, with scattered property rights, are organized and managed by local governments. There is still a big gap between the overall and individual addition, and the real play of regional resources, brands and other centralized upper wind. Industrial clusters are not simple piles, but are organic combination strictly in accordance with scientific laws; it is a natural result of the process of industrial development, and cannot be waved; cable can not be aligned, and it does not exclude the separation and integration according to economic laws and the fair cross regional layout. From the perspective of the regional industrial trend of developed countries, industrial clusters are the organic combination of industry and region, which has obvious industrial characteristics, regional characteristics and network characteristics, which can produce extremely strong competitive effect. Cable industry cluster is a successful model of the world cable industry in the development of a century, and it is also a "modular intensive area" which contains the scale benefit, lean mode and technical design of modern wire and cable industry.

The integrated large-scale production makes the cable industry with heavy materials and light industry need stable market and a large amount of cash flow, and the profit of power cable has been greatly impacted. In 2013, the production license was released, with nearly 3000 cable companies added, with the peak of 10000 cable companies, with a serious overcapacity. From 2015 to 2017, after the cruel market screening, nearly 3000 cable enterprises withdrew from the competition and stopped fighting.

In 2010, the two economic and half hour documentary "behind 52 towers" revealed the situation of overcapacity in the cable industry, which led to the production of high-voltage cables manufacturers unsaturated, and the profit space of high-voltage power cables fell sharply: for example, the original production of 2m cables made 1m cables, with profits of nearly 50%. By 2015, only 20% of the profits of high-voltage cables remained , and the high cost of various, the net profit is close to 0. The manufacturers with unsaturated capacity and poor control have already been in loss state to make high voltage and ultra-high voltage cables. Some joked that high voltage cables are no longer as profitable as the simplest distribution lines. Medium and low voltage power cables:

In terms of the import and export of wires and cables, in recent years, the products of wires and cables in China have basically met the domestic demand. The imported products are mainly concentrated in high-tech products such as 220kV and above UHV cable accessories, ultra micro paint coated wires, nuclear power station cables for nuclear island internal use, while power cables, rubber sheathed cables, extruded wires and some special cables have been exported in large quantities, with export volume one by one Since 1999, the trade of import and export of wires and cables has maintained a surplus, and the export volume has accounted for about 12% of the total annual output value of the whole wire and cable industry. In addition, the special equipment for wire and cable in China mainly depended on import before the mid-1990s. With the continuous progress of the technical level of China's electrical machinery industry, the self-sufficiency rate of special equipment for electric and cable has reached more than 70%, and some of the special equipment for wire and cable has been exported to Southeast Asia, Eastern Europe and Africa in bulk. The foreign cable manufacturers mentioned in the previous article have shrunk repeatedly, and basically quit the competition of conventional cables, and only special-purpose cable modules are reserved.

After nearly 40 years of development since the reform and opening up, China's wire and cable industry has formed a considerable scale, basically has the strength to participate in international competition. The development of cable industry has experienced dividend period and difficult dark period. As the cable industry with GDP second only to automobile manufacturing industry, it has achieved curve overtaking and gradually overtaking the world level. The following is the conclusion of the 70th anniversary of the founding of the PRC, and the theme exhibition board of technical achievements of Shanghai Cable Research Institute Information Exhibition Center.

2018

High strength aluminum clad steel core high conductivity aluminum strand

Aluminum alloy core high conductivity aluminum strand

Aluminum alloy core high conductivity aluminum wire strand

EV silicone rubber car internal high voltage line

2017

High toughness power soft cable for communication base station

High speed network data transmission cable for maritime

Shielded soft cable for robot

Wear resistant flame retardant communication cable

Super 7 data transmission cable for ships

Laying intelligent fiber composite cable behind optical unit

Torsion resistant photoelectric compliance with medium voltage drum cable

UV resistant 12 / 20kv-26 / 35kV photoelectric composite drag cable for mine

High elongation and heat resistant aluminum alloy wires with composite core for smart energy

Standard wall cable and production technology for smart energy EMU

High voltage soft cable and production technology for smart energy EMU

Super flexible stranded carbon fiber composite core for smart energy

2016

Low smoke halogen-free flame retardant and aging resistant cable materials for cables

The manufacturing method of low voltage power cable used in the containment of the third generation nuclear power plant

High performance robot arm cable

Anti interference composite data cable

High efficiency winch for communication data cable

Multi purpose high speed elevator cable

High speed data transmission cable for 1000MHz LAN

2015

150kV high voltage cable with high resistance water shielding performance

Light weight fiber composite submarine cable

Environmental protection water tree crosslinked polyethylene insulated cable fiber composite submarine cable

XX water tight cable

2014

± 160KV XLPE extruded insulated DC cable

High voltage cable with graphene conductive layer and graphene composite high semi conductive polyethylene shielded power cable

2013

The first 30 meter, 35kV, low temperature insulated high temperature superconducting cable in Baosteel

110kV XLPE insulated integrated fiber distributed temperature measuring cable

Medium voltage XLPE insulated cable water resistant cable

Insulation for HVDC cables

Flexible fire insulation layer fire resistant wire and cable, i.e. mineral insulated fire-proof cable

2012

Intelligent cable for electric communication for deep well detection

Halogen free low smoke fire retardant and spray resistant and impact resistant fire resistant cable

2011

2MW wind power cable with twist sheath

Low smoke halogen-free flame retardant fire-resistant cable for Urban Rail Transit

EPDM insulated oil resistant elastomer sheath waterproof soft cable

2009

Special fire resistant cable with rated voltage of 0.6/1kv silicone rubber insulation

2008

Special cable for EPDM insulated wind turbine

2006

The top cable and connector assembly of nuclear power plant has passed the appraisal of China Federation of mechanical industry

The qualification of class 1E class K1 cable for nuclear power plant

1987-2006

Through technology introduction and foreign large companies to cooperate or combine to form a joint venture, China's cable products technology has been comprehensively improved and developed. For example, cable for oil platform, oil pump cable, data transmission cable, 220kV cross-linked cable accessories.

1986

The full plastic local cable production line with international leading-edge level was introduced and built, and optical cable production line and quartz bar making equipment were introduced.

1985

Complete the two color line and high damping ignition line for automobile. The cable products in China basically meet the needs of all fields (including military industry) in China, with the self-sufficiency rate of more than 95%.

F glass wire and f modified polyester coating wire

1983

Introduction of 35kV dry process cross-linking production line from Sweden

Complete the lead of motor of submersible pump and high temperature conductor of polytetrafluoroethylene insulation series

500kV oil filled cable and accessories are put into trial operation on Liaojin line

1982

8000m ultra deep well load carrying detection cable, 6kV class F motor reference line and chlorosulfonated polyethylene insulated locomotive and vehicle line are completed

Self adhesive coating wire, polyester imimide coating wire

1981

Complete the kV mine cable series products

± 100kV DC oil filled cable for Zhoushan Strait

1980

Water resistant electromagnetic line

1979

Four marine cables with EPDM rubber insulation have been approved by the International Classification Society

Polyurethane enameled wire

1976

10-35kV steam crosslinked polyethylene power cable used in Shanghai Power Supply Bureau

330kV oil filled cable and accessories used in Liujiaxia power station in 1973

1970

Complete the heating cable of KM oil well

1968

110kV long oil filled cable used for Nanjing bridge crossing the river

1967

Complete the longitudinal 45 atmospheric pressure deep water sealing cable

1966

Glass film micro fine wire and polyamide enameled wire

66kV oil filled cable used in Dalian No.2 Power Plant

1964

Non magnetic enameled wire

1960

High voltage oil filling cable and accessories

35kV and below non drip oil paper insulated power cable

1959

Polyester enamelled wire and acetal coating line

1957

60 way paper rope air insulated high frequency symmetrical long distance communication cable

1956

Paper paper insulated lead wrapped telephone cable

1954

Overhead copper strand

1953

Oil exploration logging cable

1952

Glass wire class B

100 pairs of air paper insulated lead wrapped telephone cable

After the founding of the people's Republic of China, in order to meet the urgent needs of economic construction and social life, a few cable factories produced rubber insulated wires, rubber sheathed cables, overhead wires, oil paint insurance, silk wire, etc.

In the field of bare wires:

Copper clad steel wire, heat treatment and non heat treatment lead magnesium silicon high strength aluminum alloy conductor.

330kV expanded diameter steel core aluminum strand

Aluminum clad steel conductor for Nanjing crossing the river

1400mm2 soft bus for 500kV power station

500kV Zhenjiang river crossing steel core aluminum clad steel strand

Heat resistant aluminum alloy wire with steel core